SUSTAINABLE CHOICES: A PEEK BEHIND THE CURTAIN AT GOOD CHEMISTRY BREWING

This blogpost is a 15min read.

What we’re going to talk about:

Boxes

Webshop order packing

Beer packaging

Vans and deliveries

Energy

Equipment

CO2

Supplier relations

Have you ever considered what impact the beer you drink has on the environment?

When you’re in a cosy pub with a cold one on the table, we can see why it might not have crossed your mind. But here at Good Chemistry Brewing sustainability is at the heart of everything we do. It’s been written into the core of our business since Bob & Kelly first started GCB nine years ago.

We wanted to spend the first part of this year doing more to explain our sustainability journey, and if you’ve seen posts on social media, tried our collaboration beer Brighter Later, or read our earlier Good Lager blog, you’ll already know a little. This blogpost aims to bring together the sustainable choices we’re making, thinking about, committing to and moving towards – we believe ‘being sustainable’ is not an end goal but a constant process of improvement.

We will continue to be thoughtful and considered in our decision-making, so you can be confident that what we tell you will be honest, transparent and backed up by robust science – good chemistry at its best!

So what is sustainability?

Sustainability comes in many different forms depending on what is most important to you or to your business. A very general definition says that Sustainable practices support ecological, human, and economic health and vitality. This means that what you do needs to be considered in its impact, but also viable in terms of cost and longevity of the project.

For example, there’s not much point installing a brand new piece of kit in the name of environmental sustainability if you aren’t going to be able to maintain the costs long term.

Since 2015, sustainability has been at the forefront of Bob & Kelly’s minds. For us, it’s not just about brewing great beer; it’s about nurturing our business to thrive long-term, building a viable and sustainable brewery, in both environmental and business terms, that does what it can to tread carefully.

Why are we telling you about this?

Our hope is to shine a light on the things we do at Good Chemistry that are making a difference to our impact on the planet and which contribute to the sustainability of our business. Of course this includes taking steps to actively reduce our carbon footprint, but also means our commitment to making the Good Chemistry brand successful so we can continue to do things that make a difference for a long time to come.

So what do we do?

Well first of all, we think small. The smallest things we use in the brewery often add up to massive quantities over the course of a week or month, or especially a year. So without further ado, lets break this down:

BOXES…

Any new carboard boxes we buy in for our cans are FSC certified (read more about FSC certification HERE). This means the raw materials are sourced from responsibly managed forests. That’s a nice easy one.

Another thing we do with our boxes is make every effort to re-use as many as we can. We sell a load of cans from our Can Shop at the Brewery itself, in our own pubs The Good Measure and Kings Head, and through our online webshop (thanks of course to all our wonderful customers!). But we send out the majority of our cases of cans to our pub, restaurant, cafe and bottle shop cusomters. So it’s important to us to work with both our trade stockists and local webshop customers to encourage the return of boxes for future re-use. And, where cans are re-packed into stronger boxes designed to withstand the conveyor belts and hasty service of the courier system, or sold directly to you in the Can Shop, the boxes that are emptied go straight back on the pile for the next canning run – and perhaps even beyond that. Through these simple but thoughtful measures, we were able to re-use a whopping 16.6% of boxes last year.

That might sound modest, but it represents hundreds of boxes, and we can only see this number rising as we more widely collaborate with our stockists and get the word out to our regular home delivery customers to return their boxes. You’re welcome to bring your empty boxes back in to us at the Can Shop, The Good Measure or the Kings Head, or next time we deliver give Liam your previous boxes and he’ll take them away for you.

WEBSHOP ORDER PACKING…

When we pack cases of beer for sending out via courier, we make every effort to pack them as properly as we can so that nothing moves around and gets damaged in transit. This means saving any secondary packaging from parcels coming to us at the brewery, to pad out any gaps. We are able to re-purpose so much that we don’t have to use any brand new padding materials and actually give surplus to a local small craft business to use in their boxes for shipping.

We pack all of our courier deliveries in double walled boxes. This minimises the risk of damaged cans during transit from our fridge to yours. It’s been tried and tested that by doubling up the thickness of the box wall, we reduce the chances of your cans getting knocked about during delivery – and if we have to re-send your case due to damage it costs twice as much in raw materials, actual beer and fuel than if we just use what is, essentially, two boxes.

We obviously still want to make everything look good so our branded tissue paper is from noissue. This is made from a minimum of 30% recycled materials and the rest is FSC certified, new acid-free virgin pulp, which is also fully home-compostable and printed with soy based inks. As it is considered a ‘low grade paper’ it’s not suitable for recycling, but is perfect for re-using or can be composted at home or put in your food waste bin.

BEER PACKAGING…

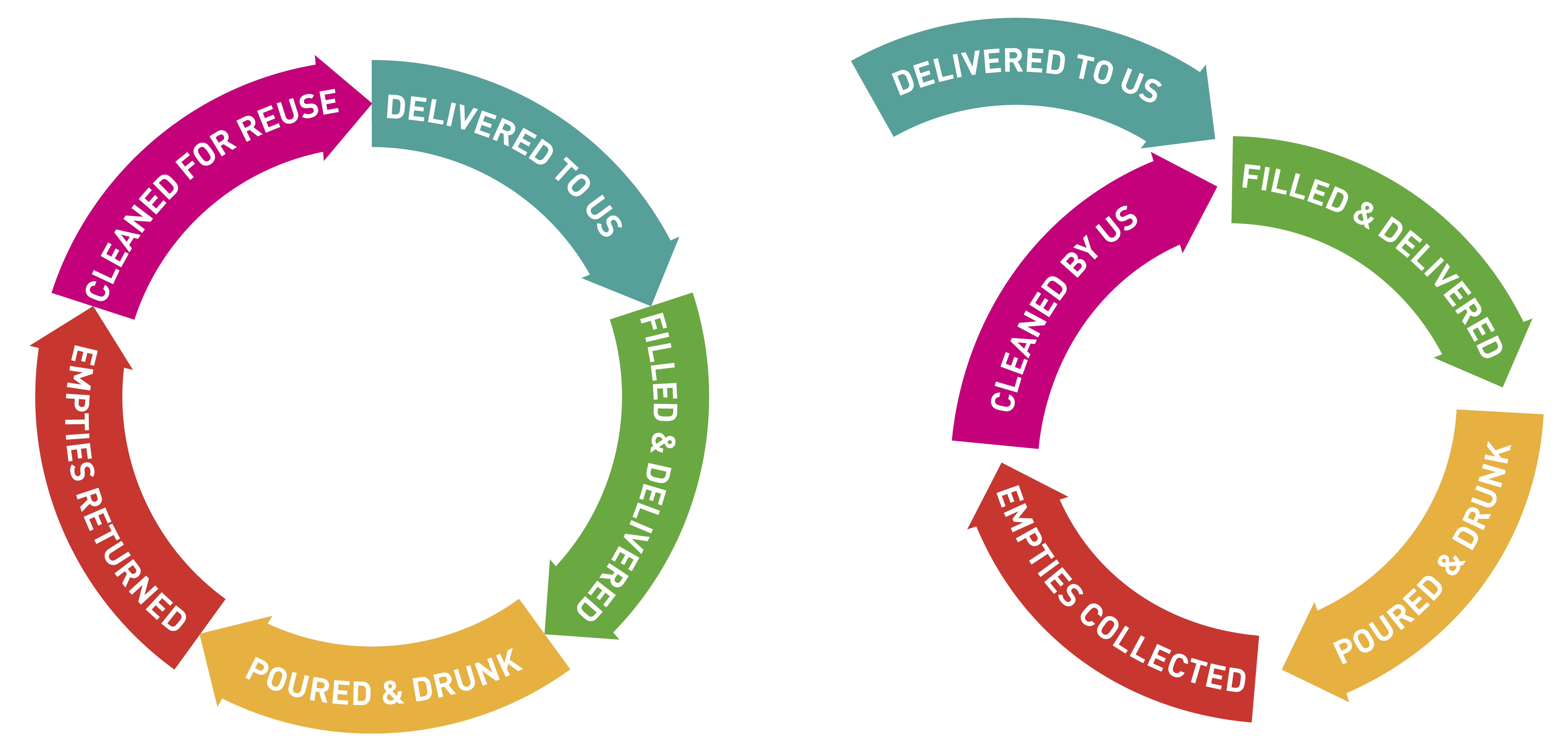

We package all of our beer into metal containers. Whether that is stainless steel kegs and casks for pubs, bars and restaurants, or aluminium cans for shops and filling your own fridge with. Steel kegs and casks can be washed and reused, and aluminium cans can be recycled an infinite number of times! We use our own steel casks for beer going out into Bristol to our brilliant customers locally. For those customers further afield we work with Close Brothers Brewery Rentals based in Herefordshire. The steel kegs and casks are part of a closed loop system operated by Close Brothers. They have a pool of kegs and casks that get rented out to breweries around the UK. It works like this:

Close Brothers supply us with clean kegs/casks -> filled by us in St Philips & delivered to pubs -> dispensed by pubs & drunk by you -> collected by us/other breweries & returned to Close Brothers -> keg/cask is cleaned … and round and round again.

This allows us the flexibility of not having to get our own kegs and casks back to the brewery to refill them, which has cost and time implications, not to mention the additional hours and miles spent on the road running around just to collect them back, and the huge potential for them to go missing and not be returned to us at all.

We have recently invested in a keg washer. This will allow us to collect Close Brothers kegs we already use in Bristol and clean them ourselves (using renewable energy of course), minimising the transport involved in their use cycle, and cutting emissions from delivery to us. The addition of in-house keg washing is a significant step in our sustainability journey, and we will hope will make a tangible impact on our carbon footprint as well as the efficiency of our brewery operations.

We have never packaged into KeyKegs (those tall plastic kegs with the silver bags inside) and, where possible, do our best not to buy beer packaged into them at our pubs. KeyKegs and other single-use plastic kegs can’t be washed and reused in the same way steel kegs can, they need to be broken down and re-made, adding to the processes and energy costs involved. They can only be recycled by taking them to a drop-off point where they can be crushed, baled and sent to the Netherlands. And if a pub isn’t able to get the kegs to a recycling drop off point, then they would end up in landfill or an incinerator.

Cans can’t be reused like steel kegs, but they are made from aluminium making them infinitely recyclable. So, once you’ve enjoyed your can of Kokomo or Good Lager, rinse it out and pop it in your recycling bin, ready for its own wash and refill of sorts.

Incidentally, if you’re looking to make the sustainable choice at the bar, cask beer is generally the one to go for. This is beer dispensed from handpull or by gravity direct from the cask, and is a quintessentially British way of packaging beer. Re-usable containers, low-intervention packaging methods, generally smaller distribution areas, and minimal CO2 inputs (see section further down) make cask beer the low-fi sustainable choice. Because it’s only available from the bar, too, it has the added benefit of supporting pubs, something we here at GCB also whole-heartedly agree with.

VANS AND DELIVERIES…

We’ve been getting the most out of our van since we started – repairing and patching it up over the years. But when Bristol City Council announced the Clean Air Zone (CAZ) we felt it was a sign. We got everything we could out of our old van over the years but, with the Council’s support, we were able to trade it in for a more efficient and cleaner, newer model.

Initially we had high hopes for getting a fully electric van, however due to the much higher purchase costs as well as not having a private yard for charging, we opted for the next best thing: a Clean Air Zone compliant second-hand diesel van. This has meant that although we aren’t yet scooting around the city powered by 100% renewable electricity like we had hoped, we are emitting fewer pollutants and averaging a greater Miles Per Gallon (MPG) with better engine efficiency. A small, but not insignificant, victory in our eyes – we are a small business and some costs are just out of our reach.

In addition to just having a better van, we also do all we can to minimise our driving around the city by operating a postcode-specific delivery schedule and taking out any webshop orders we can alongside our trade orders. So while you might not always get your beer the day after you order, you can rest easy in the knowledge that we’ll be with you on your postcode-specific delivery day, and will have saved a few van miles in doing do! (Find out your usual delivery day on our webshop HERE.) And if you order at the optimum time, you might just get your delivery within mere hours of ordering!

Delivering in this way massively reduces the number of times we drive to and from the same place. Our mileage around the city is so much more efficient delivering like this.

We’re always on the lookout for greener options for delivering beer around Bristol so watch this space for more innovations to come!

ENERGY…

Our brewery in St Philips and our pub The Good Measure are both supplied with 100% renewable energy. Our newest (oldest!) pub, the Kings Head, is unfortunately in contract with a non-renewable supplier. However, when that contract comes to an end, we will make the switch to a renewable supplier. The only gas we use is at the Kings Head, where we have a brand new boiler to be as efficient as possible.

We often talk about the possibility of solar panels on our brewery roof however, after a survey we found that our roof would need to be fully replaced in order to hold the weight of a solar array. The carbon cost associated with replacing a perfectly functional roof plus the embedded carbon from creation of solar panels makes a 100% renewable energy tariff the most sensible and least carbon intensive option for us at the moment. Should the roof start to degrade and need replacing, then it would certainly be something we look at again.

EQUIPMENT…

The most energy intensive processes in the brewery are around the heating and cooling of wort and beer. For a brewday we need to heat around 2,000 Litres of liquid from ambient temperature to boiling, and keep it at a boil for a full hour. Our kettle came with two 36kW elements, which were very effective at this! But, following investigation, we found that we could maintain a boil with only 18kW of power, so we had one of our elements rewired. This improvement has halved the amount of energy we use during the boil section of a brewday.

Conversely, the other major use of energy at the brewery is in cooling the wort after the boil and controlling the temperatures of our tanks. In order to make this process more efficient we recently replaced our brewery chiller with a new, more efficient model. This chiller modulates the amount of power it uses depending on how much chilling it needs to do. If it needs to make a big difference to temperature it will use more chilling power to bring the temperature down quickly. But if the temperature difference is only small, such as when maintaining beer temperature during fermentation, it will use less power.

But why stop there? The chiller works by cooling a glycol/water mix and pumping it round a circuit of pipework connected to all of our tanks. So, the other efficiency improvement we have made recently is to overhaul our chiller circuit pipework, installing larger pipes and much better insulation. The upgraded pipework and insulation makes the chilling more efficient, reducing heat pickup. We have also eliminated most of the corners in our previous circuit. Corners create turbulence in the coolant, and turbulence promotes heat transfer, which we want to avoid if we’re looking to avoid wasting energy. A smoother and more efficient flow reduces our energy consumption and further improves consistency in the beers we make.

CO2…

Carbon dioxide (CO2) is a natural by-product of fermentation and is released when making beer. CO2 is also used in breweries to purge oxygen from tanks and kegs, to avoid beer going stale. Like all breweries in Bristol, we buy in CO2 from national suppliers. However, breweries of a larger size are able to install equipment to trap and process the CO2 from fermentation so it can be re-used in the brewery and reduce the amount that needs to be bought in. This can be a substantial efficiency saving for breweries with larger Capital budgets, however there are still thoughtful choices that smaller breweries like us can make.

The CO2 we use is a byproduct of Anaerobic Digestors (food waste processing plants) and the British Sugar Plant based in Norfolk, where CO2 is captured from the fermentation of beet for sugar production.

Large scale carbon capture plants have efficiencies that we couldn’t begin to replicate on a scale as small as at our brewery. For a start the companies that have these large carbon capture facilities will have teams of people dedicated to the running and maintenance of the carbon capture equipment, ensuring the quality of CO2 as well as the efficiency of the equipment

As we grow, an in-house CO2 recovery system may become cost effective, and we will continue to monitor developments in technology. The cost savings for breweries with money to invest in these systems can be large, but the extent of the environmental benefits at a company of our size at this point is unclear.

SUPPLIER RELATIONSHIPS…

BarthHaas X (our main hop supplier) and Simpsons Malt (our main malt supplier) are both committed to improving their sustainability credentials. Both companies have commitments to helping their farmers use better and more efficient farming techniques and are investing in the future, through developing climate resilient crops and improving equipment to support the growing of crops. Simpsons are even going as far as mapping the carbon footprint of each type of malt that is produced. All of this allows us to make better and more informed choices when designing beers and ordering ingredients.

We’ve already collaborated with BarthHaas X to showcase one of their new climate resilient hops, Tango. You can read the full blog about it HERE and buy cans on our webshop here.

And we have a cask-only collaboration with Simpsons coming out soon! We used this opportunity to pick the brains of the lovely people at Simpsons and took a deep dive into the different types of malts we have access to. We’re creating a fantastic beer that will showcase malt supported and produced by Simpsons to allow us to make more informed and responsible choices in brewing.

You may have also read our Good Lager blog, with its focus on yeast, when we first brewed that, back in Nov 2021. This is here, in case you want to refresh your memory, or didn’t see it at the time.

So what’s next?

Well, if you’re still reading… THANK YOU! Our sustainability journey is a continuous evolution, so we know this is just a snapshot – but it’s good to take a moment to share and reflect on what we’ve achieved and look forward to the steps we’ll take in the future.

We understand small, often overlooked, things in the brewery amount to massive impacts. From casks to suppliers, and cans to boxes, our focus on sustainability is unwavering. We’re not just reducing our carbon footprint; we’re committed to continuous improvement in every aspect of our brewing process.

As we raise a glass to our achievements, we also raise the bar for ourselves. Our journey is far from over. We hope you’ve taken something away from reading this, and if you have any questions please do get in touch. You can reach Bob and Lorin at cheers@goodchemistrybrewing.com. We’d love to hear your thoughts on our progress and future developments we can make, and hope you’ll stick with us as we strive for a more sustainable future, knowing that each choice we make today impacts the world we’ll brew in tomorrow.

Cheers!

(Pictured below: Ed (brewer), Lorin (operations manager & sustainability lead), Liam (drayman & head of engineering), Bob (owner, founder, sustainability guy), Elliot (brewer), Kelly (owner & founder), Will (sales), Jim (sales), Dan (marketing & design) – cheers from us)